Knowledge in the form of important data will be linked with products and machines in the future. The availability of all information in real time already represents high value today. Networking all of the entities that participate in adding value opens up additional potential, as does the capability of deriving the optimal ow of value from data. Fabrication processes and transport of the goods are merged through networking in the Internet of Things, while services and data are automatically matched in real time to client preferences or to adaptable production requirements. Refined software solutions, intelligent sensors, as well as measurement and test systems contribute to quality assurance as well as to process and logistics optimization. The fabrication industry is still the backbone of business, particularly in Germany, which is why new paradigms must first be proven – not only regarding their effectiveness, but also their dependability. For this reason, norms and standards are required that assure protection of shared data and a high fail-safe level.

Manufacturing and logistics

Industrie 4.0 ...

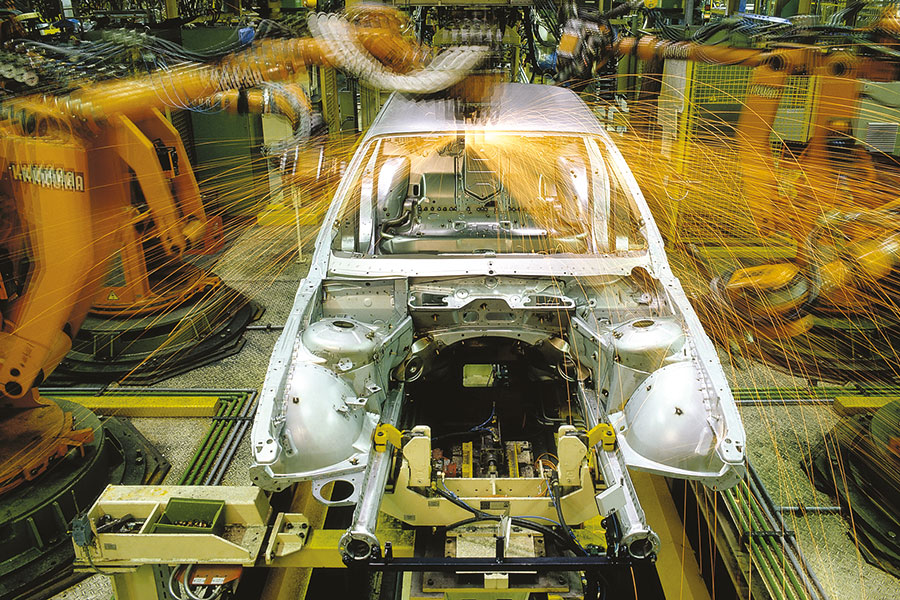

Industry 4.0 brings people and machines closer to one another. The fourth industrial revolution in manufacturing comprises what is known as cyber physical systems, for one. These link real products, tools, and production facilities in the virtual world. The economic networking of intelligent machines facilitates distributed, automated control and increases productivity as well as flexibility. For another, Industry 4.0 also describes new diverse opportunities for integrating human work into the production process as well.

Object identification and positioning recognition are included in the cornerstone technologies of Industry 4.0. With the help of RFID, sensors, and individualized software solutions, products and goods always carry the essential information about their state and their position with them. Loading and unloading, sorting, shipment, and assembly tasks will be automated by software. This increases the speed and also the quality, if correctly implemented. For people, industrial automation importantly means less physical or dangerous work.

Measurement and testing systems facilitate process-integrated quality assurance of manufacturing and logistics. Where previously only spot-sampling types of monitoring were feasible, today all products can be checked for material, manufacturing, or software defects based on standardized rules. With the development of software architectures for logistics and manufacturing facilities, standards for guaranteeing quality and safety are already being integrated. Through the use of virtual models, components and entire products can be made in advance in realistically appearing and sounding fashion and assessed. Automated, networked software systems check products and machinery as well as operational processes and manufacturing control systems. und Produktionsleitsysteme.

Project ProVis.Agent

Example project from Fraunhofer IOSB, Karlsruhe

Guidance systems monitor and control automated facilities, most of them manufacturing plants. The focus of Fraunhofer research is on fabrication engineering – but the systems are also employed in the processing industry, monitoring of computer centers, and other areas of application. ProVis.Agent® is the guidance system for control and monitoring of all production equipment for fabrication of the C-Class series of vehicles at the Mercedes Benz factory in Bremen, Germany, and employed in the plant’s manufacturing, paint, and assembly lines.

Scientific publications

| Jahr Year | Titel/Autor:in Title/Author | Publikationstyp Publication Type |

|---|